5 major difficulties in high-end furniture customization!

2023-12-05 10:29

The furniture customization discussed in this article is non-embedded movable furniture customization based on artistic and emotional needs. Such as sofas, coffee tables, dining tables and chairs, beds, desks and other furniture. Customization of this type of furniture is mainly based on traditional manual processing with small machines or intelligent robots. The real emphasis is on the needs of personalization and high-end.

High-end furniture customization for events is difficult to mass produce due to its outstanding personalization and high manual requirements. There are many difficulties that require specific processes:

Difficulty one

It is to accurately grasp the needs of customers.

Consumer needs are diverse. Some needs can be met, such as the need for the seating feel of the seat, the need for the inclination of the backrest, and the need for the color of the material;

Some demands require high costs, such as the demand for accessories for grinding tools. The cost is relatively high and needs to be explained clearly to the customer;

Some needs cannot be met, such as shapes and designs that cannot be met by existing process technology. This needs to be explained to the customer to avoid disputes.

Difficulty 2

Grasp the linear shape and aesthetics of the product.

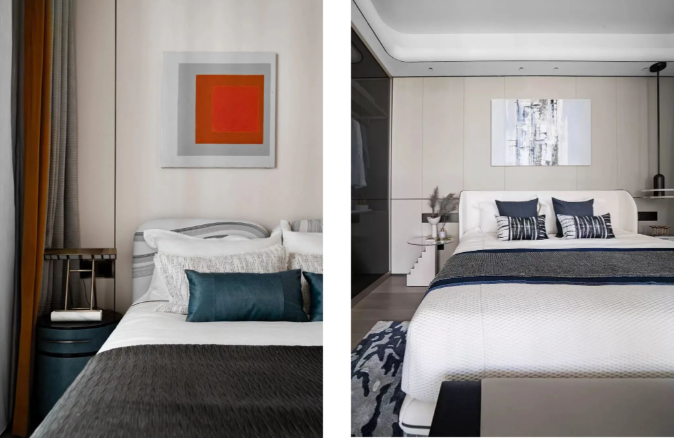

The first point of the market trend of high-end customized furniture is the transformation from practicality to aesthetics. Therefore, customized furniture often has particularly high requirements for the aesthetics of the product. Especially some products with strong lines are more difficult to grasp.

A designer has a famous saying: Curves belong to God, straight lines belong to humans. This shows that the beauty of curves is an artistic factor that is particularly difficult to control. Therefore, after determining the customer's needs for the material, size, and fabric of the product, the production company needs to design detailed drawings for confirmation by the customer and the customer's designer. In order to arrange production.

Difficulty three

Difficulty of the process.

Consumers with customization needs tend to choose relatively high-end products, which are difficult to satisfy in the market.

Modern high-end movable furniture customization requires furniture manufacturing companies to be familiar with key furniture manufacturing processes all year round, including the combination and conversion of solid wood, hardware, and software. Only in this way can the details of various process combinations be handled well.

Difficulty four

The selection of materials is also a link in customization that tests service capabilities.

For example, hardware processing includes electroplating, sandblasting, powder spraying, nano colorful spraying, baking paint, or plain or random grain processing. Or hammering crafts and so on. Glass can be processed by hot bending, color, wavy pattern, wire lamination, surface hand-painting or engraving;

Acrylic has color changes, abrasive shapes, etc., and marble also has many options. This requires custom manufacturers to have a considerable number of supplier resources for customers to choose from; they also need to understand and apply different material properties, expansion and contraction ranges, and toughness.

Difficulty five

Establishment of production system.

The difficulty in customizing high-end movable furniture determines that its production system is different from traditional furniture manufacturing. The production team needs to shift from assembly lines to being dominated by skilled masters of various processes. In the front department of production, a design team needs to be set up to meet the perfection and research of drawing processes. The production process is as follows:

Contracts and lists based on customer needs ----- Deepening of drawings and processes based on customer needs ----- Communicate with customers and review drawings, materials, and dimensions with customers or customer designers ------ Conduct pre-production Process review and manufacturing planning-----Deepening of material drawings based on process and manufacturing process-----Arrange manufacturing according to the process-----Quality monitoring of the process-----Customer blank inspection when necessary Or finished product acceptance.

To sum up, the customization of high-end movable furniture requires proficiency and exquisiteness in various crafts internally, as well as a corresponding design team and skilled craftsmen; externally, it requires familiarity with domestic and foreign furniture brands and new materials. There must also be familiarity and interaction with furniture-related supply-side resources. It is also necessary to have an in-depth understanding of customer needs and market analysis, and to continuously communicate with customers and follow up on manufacturing.